75 Years of Casting Experience

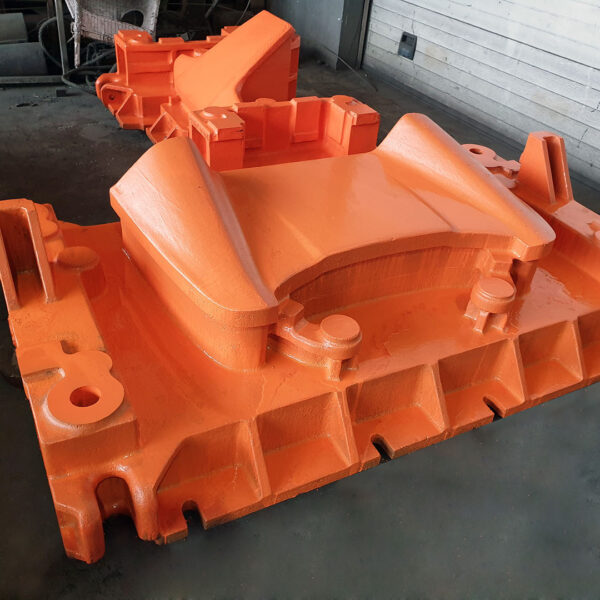

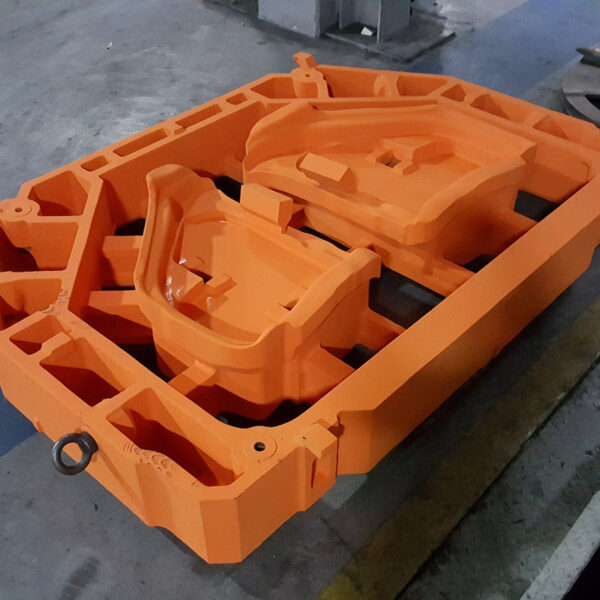

Production of casting parts -which is the main operation of the company- has developed with the years of experiences and fund of knowledge in the sector. The main target is to supply complex castings requested by today’s technology at the most suitable timing and in highest quality.

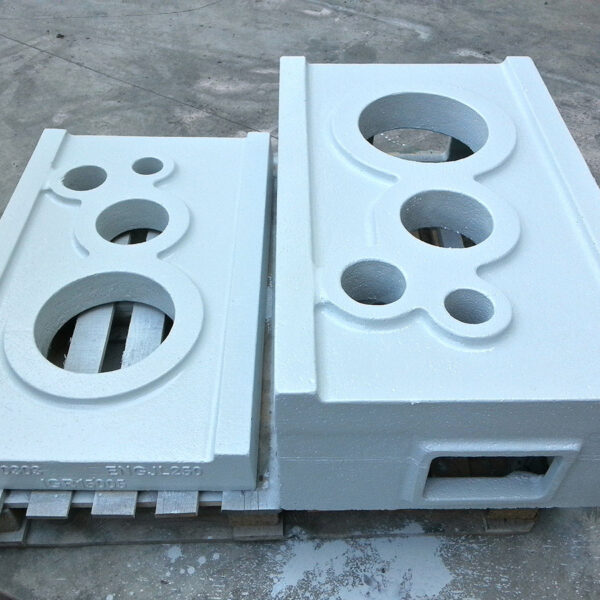

Gray & Nodular Iron and Cast Steel

The company has a team of experts on production and quality control of grey iron, ductile iron and steel casting. The company also owns a full equipped metallurgy laboratory. Abilities like spectral analysis, microscopic structure examination, destructive and non-destructive testing possibilities, solidification and flow simulation via Solidcast software enables the company to lead a certificated and successful production progress.

Foundry Capacity

Annual casting capacity exceeds 20.000 tones. The company can produce cast iron parts from 100 kg to 50 tons per piece and also cast steel parts up to 30 tons per piece. Thanks to logistic improvements and newly-bought Inductotherm induction melting furnaces the company has improved its productivity highly.

50 Tons Per Piece

İğrek Makina Foundry can make the cast production up to 50 tones by the piece thanks to logistic improvement and newly-bought Inductotherm induction melting furnaces.

Melting Capacity

| Melting Furnaces | Power (kW) | Capacity (kg/sa.) |

| Inductotherm | 7500 | 15.000 |

| Inductotherm | 2500 | 7.000 |

| Inductotherm | 2500 | 5.000 |

| Inductotherm | 2500 | 5.000 |

| Inductotherm | 750 | 1.000 |

| Inductotherm | 750 | 1.000 |

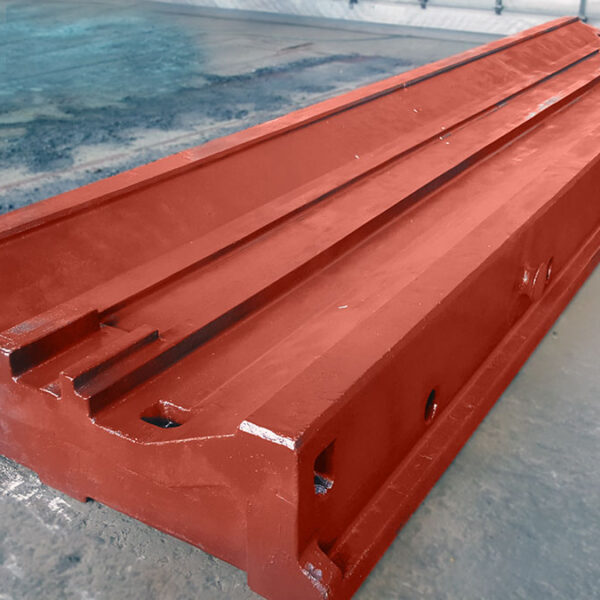

- Hand moulding process in boxes up to 15 m length

- 4 mixers for resin bonded sand

- Thermal and mechanical sand reclamation units

- Mg wire treatment wire station for nodular iron

- 6 InductothermTM Electrical induction furnaces:

- Liquid metal capacity: 35 tons

- Total melting power: 13.500 kW

- Shot blasting, welding, heat treatment and painting utilities